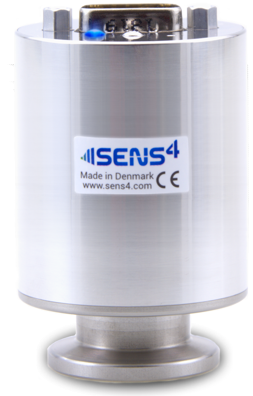

VDM-5 DiCAP™ DUAL DIAPHRAGM TRANSDUCER

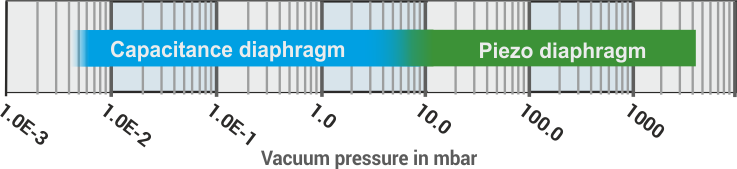

5×10-3 to 1333 mbar / 3.75×10-3 to 1000 Torr / 5×10-2 to 1.333×105 Pa

CAPACITANCE AND PIEZO DIAPHRAGM COMBINATION TRANSDUCER

- Measurement range of 5×10-3 to 1333 mbar (3.75×10-3 to 1000 Torr)

- Gas-independent diaphragm sensors

- Ceramic capacitance diaphragm gauge and Piezo diaphragm

- Mountable in any orientation without impact on performance.

- Programmable voltage output signal with other vendor emulation

- Digital RS-232 or RS-485 interface

- Three solid-state set points for vacuum process controlling

- Optional Parylene sensor coating for aggressive environments

- Affordable compact multi-sensor solutions

Designed, engineered and made in Denmark

The VDM-5 transducer establishes new standards with an all-in-one measurement solution for a wide selection of vacuum applications. It differentiates from any other vacuum gauge by offering an overall cost-effective gas independent measurement from 5.0E-3 to 1333 mbar

In vacuum applications where the gas composition or type can change, traditional gas dependent Pirani gauges will result in measurement deviation from the actual pressure. The VDM-5 transducer uses a precision capacitance diaphragm gauge (CDG) sensor that eliminates the gas dependency and provides accurate measurements also when the gas properties change.

The integrated heat-loss MEMS Pirani sensor extends the measuring range down to 1E-6 mbar and provides a novel automatic zero adjustment of the capacitance manometer that eliminates the common needs for manual zero adjustment of traditional capacitance diaphragm gauges.

Enabling use in harsh environments

The VDM-5 can also be used in tough vacuum applications where corrosive, and media may be present.

is engineered not only for clean nitrogen vented load-lock applications in the semiconductor industry, but also for applications where particulates and aggressive media may be present. For applications where the sensors can be exposed to corrosive or aggressive gases, the SmartPirani™ is available with conformal protective coating serving as an effective barrier.

Depending on the actual application, the VDM-5 transducer series offers a choice between an optional ceramic or Parylene protective barrier to guard against corrosion or oxidation of sensor materials.

Programmable transducer settings and parameters

The transducer settings and parameters can be user-programmed to control vacuum system and application process parameters.

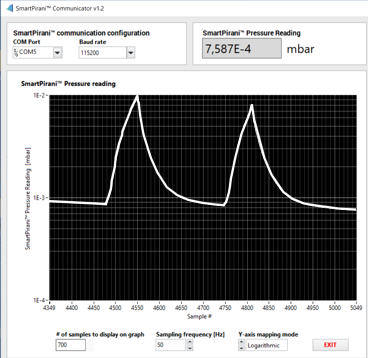

The digital RS-232 or RS-485 serial interface can be used for diagnostics, predictive maintenance, service, calibration, setpoint configuration, analog output scaling, and acquisition of real-time vacuum pressure measurements for on-screen visualization.

The serial USB programmer in combination with the free, intuitive configuration software is a plug-and-play solution for transducer programming, real-time measurements, and diagnostics.

Ceramic is highly corrosion resistant and is a well-proven material for vacuum sensor diaphragms in capacitance diaphragm gauges.

Parylene, a unique polymer with highly corrosion resistant and hydrophobic properties, is specifically designed for medical applications such as lyophilization and hydroperoxide plasma sterilization of medical devices.

In vacuum systems and processes, where vacuum sensors may be prone to damage from particulates, the VDM-5 DiCap™ transducers are available with a protective baffle, acting as an efficient barrier against macroscopic particles. Combining these protective coating options, the DiCAP™ transducers are well-equipped to handle challenging vacuum environments.

Controlling vacuum pressure with reliable and robust setpoint relay control

Several vacuum pressure parameters need to be accurately and reliably controlled in many vacuum applications. The VDM-5 transducer has three independent solid-state switch relays that can be configured to control venting, the transfer chamber gate-valve, and the load-lock door.

Compared to traditional electromechanical relays, the solid-state relays offer superior reliability and faster switching time while providing arc free contacts and generates no EMI (electromagnetic interference) when switching contacts. The VDM-5 control relays are designed to last and are UL listed, CSA recognized, and EN/IEC 60950-1 certified for maximum confidence when used to control critical vacuum processes and high-cycle applications.

For applications where atmospheric switching functionality is required, like load-lock vacuum systems, the VPM-17 TriCAP™ ATM offers the precision atmospheric switch capability. For applications where lower measurement capability is required the VPM-15 TriCAP™ transducer offers measurement down to 1E-6 mbar.

Analog voltage output for external readout

A wide selection of analog output scaling options to emulate other vendors’ vacuum gauges and transducers is available. An optional secondary analog output enables external monitoring of both the full-range vacuum pressure and the pressure signal relative to atmospheric pressure.

Customized settings

The transducer can be delivered with a custom configuration to match specific application requirements. Examples of pre-configured options include measurement range, vacuum pressure unit, setpoint configuration, and output signal scaling. Customized products will be assigned a unique part number for easy and simple future reordering.

APPLICATIONS FOR VDM-5 DiCAP™ VACUUM TRANSDUCERS

- Furnace heat treatment

- PVD coating of glass, optics, tools, packaging, decorative

- Refrigeration manufacturing and service

- Semiconductor processing equipment

- Vacuum pump service

Rethink vacuum gauging |

MORE INFORMATION

SENS4 FEATURED KNOWLEDGE CONTENT

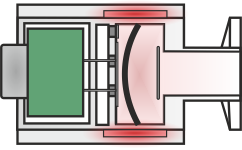

CAPACITANCE DIAPHRAGM GAUGE EXPLAINED

A capacitance diaphragm gauge, commonly referred to as a CDG, measures vacuum gas pressure by direct measurement of the applied force on the surface of a thin diaphragm.

A traditional capacitance vacuum transducer measures absolute.........