Accidents and mistakes during equipment installation or maintenance, such as reversing the polarity of a DC power supply connected to a pressure, vacuum, or temperature transducer or transmitter, can lead to serious consequences. Without proper safeguards, reversing the DC supply voltage polarity can damage the sensitive electronics inside these devices, potentially causing costly downtime and requiring replacement.

To prevent such scenarios, many transducers and transmitters are equipped with reverse polarity protection circuits. This critical feature ensures that the device remains unharmed if the power supply polarity is accidentally reversed. The protection circuit works by interrupting the flow of power to the device’s electronic components, shielding them from electrical damage.

Reverse polarity protection is particularly vital in industrial environments where DC power supply systems often deliver significant power. Without this safeguard, the reversed current could cause permanent damage to the connected device and, in extreme cases, create a fire hazard. Ensuring that transducers and transmitters are equipped with reverse polarity protection enhances safety, reliability, and operational continuity in demanding industrial applications.

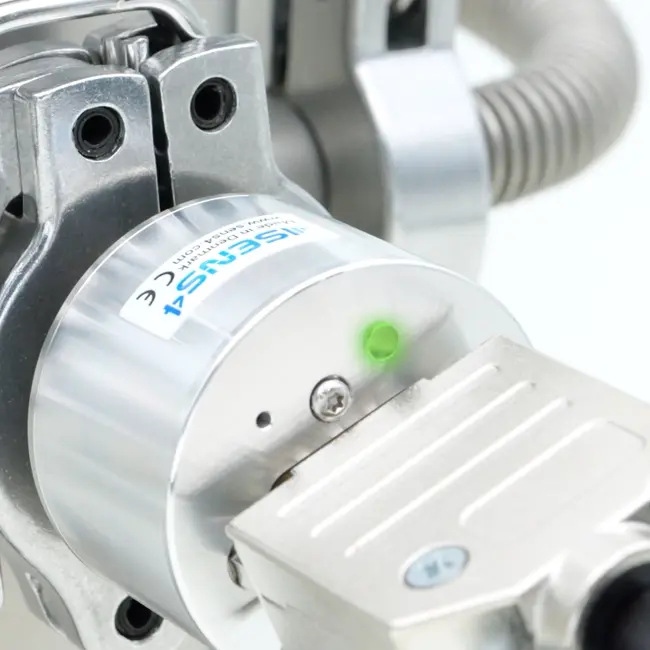

Vacuum Transducers with reverse polarity protection is from Sens4.

Learn more about product solutions >