All-in-one Multi-sensor Transducer Solution

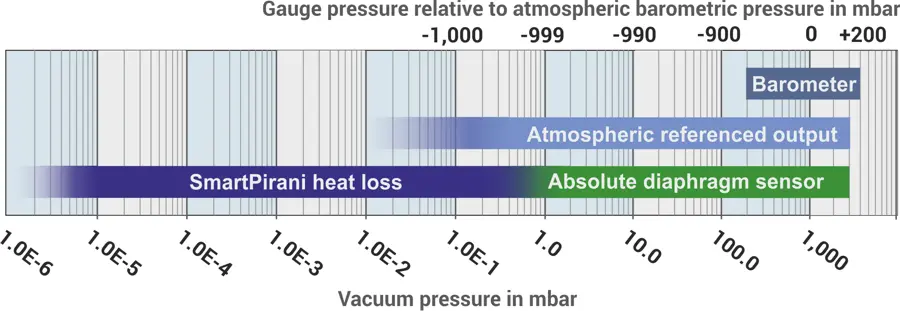

The VPM-7 is a true multi-sensor transducer featuring four pressure outputs: a barometric ambient sensor, a wide-range heat-loss Pirani sensor, an absolute diaphragm sensor, and a signal relative to atmospheric pressure, all working together to optimize accurate pressure control in a modern load-lock vacuum chamber. The diaphragm sensor provides a precision gas-independent absolute reading from 2 to 1333 mbar (1.5 to 1000 Torr).

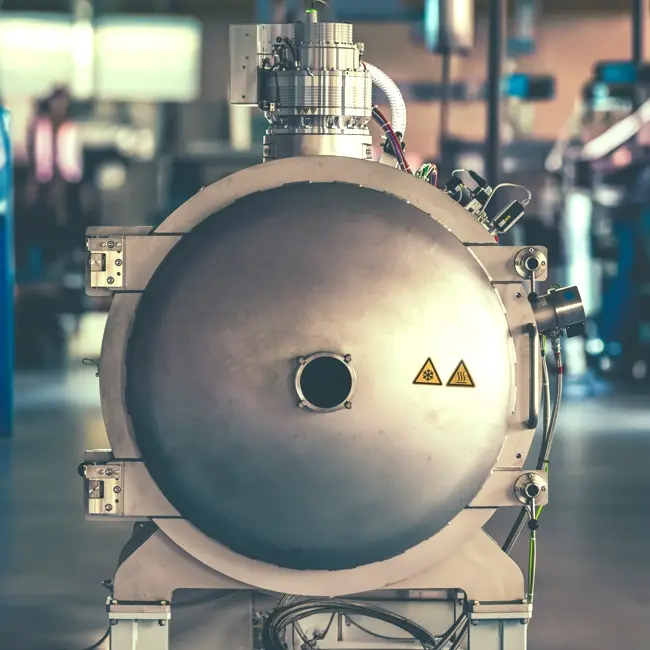

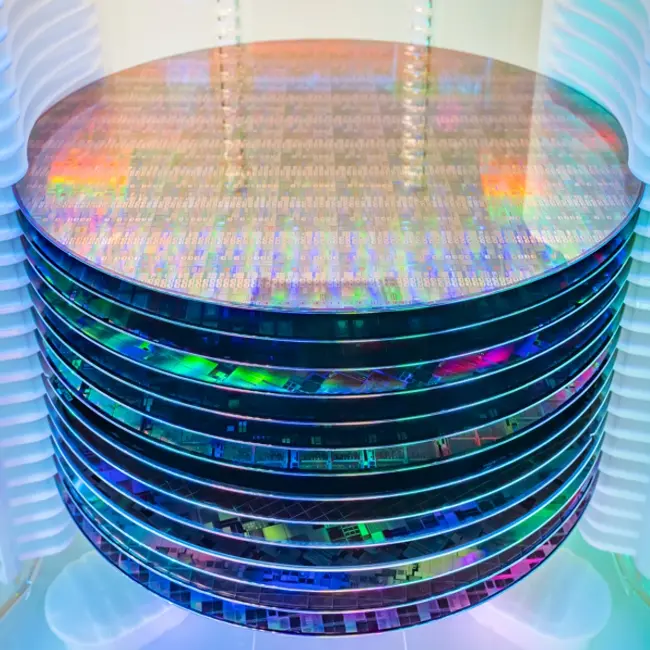

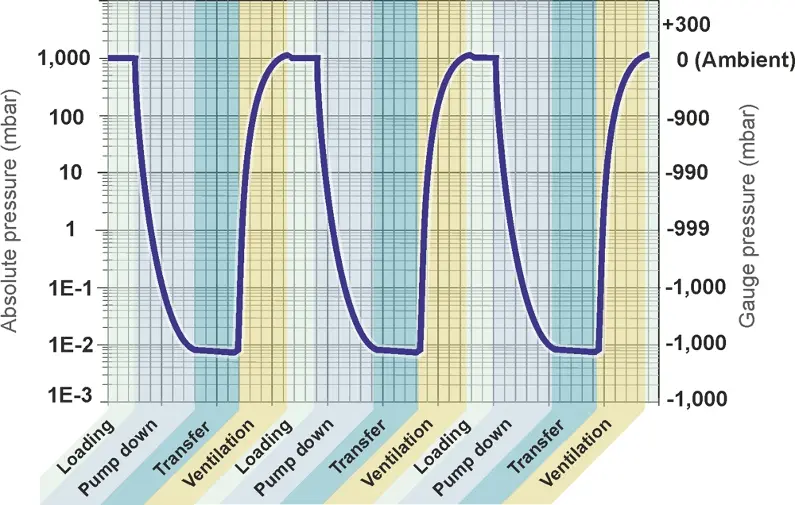

A load-lock is a vacuum chamber used to load devices, such as semiconductor wafers, from ambient air pressure into a vacuum processing chamber. The load-lock typically cycles between atmospheric pressure and the appropriate vacuum level needed to transfer the wafers to the processing chamber. Accurate pressure control within the load-lock is crucial to prevent contamination from ambient air and particulates, safeguarding both the chamber and the wafers.

Measure and Control Load-lock Processes

The VPM-7 SmartPirani™ ATM is engineered for best-in-class measurement and control of vacuum gas pressure. Several output options provide more than just a pressure measurement signal.

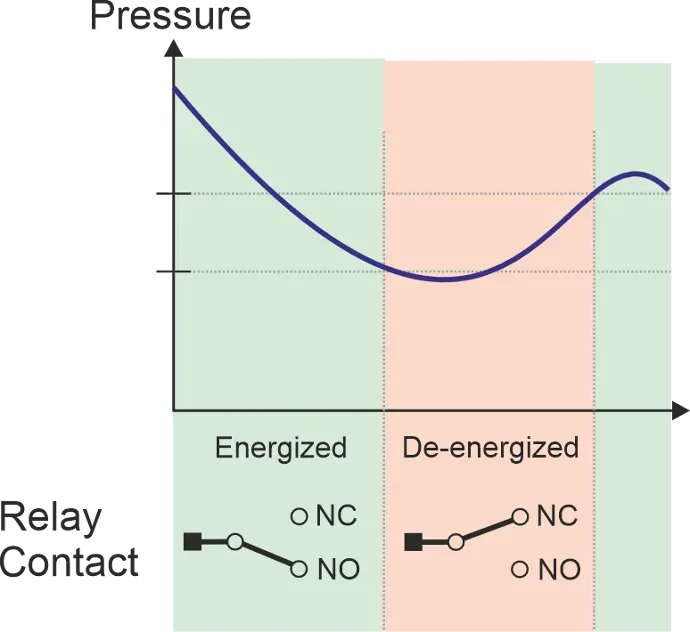

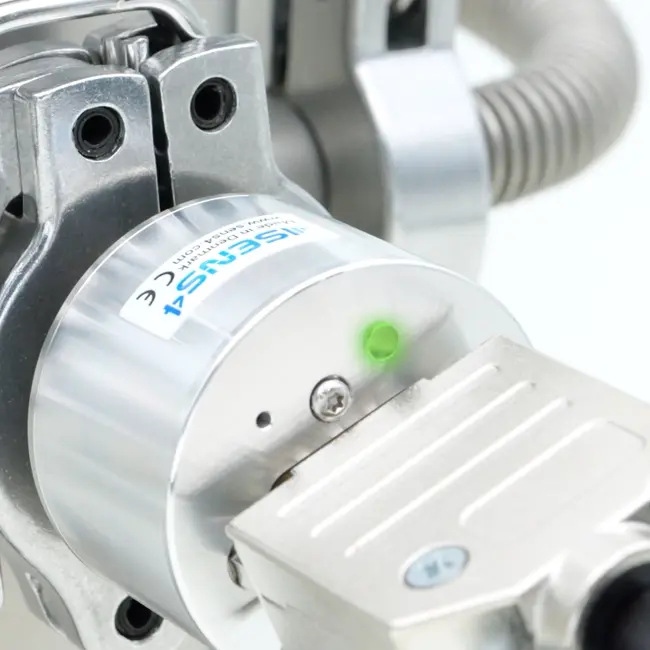

Reliable Setpoint Relay Control

The three independent solid-state switch relays allow for external control of load-lock pressure cycle including pumps, valves, safety interlock circuits, PLCs and other equipment.

Unlike electro-mechanical relays, solid-state relays deliver greater reliability and faster switching times, with arc-free contacts and no generation of EMI (electromagnetic interference) during switching.

SmartPirani™ ATM relays are engineered for durability and are UL-listed, CSA-recognized, and EN/IEC 60950-1 certified, ensuring reliable performance in critical vacuum processes and high-cycle applications.

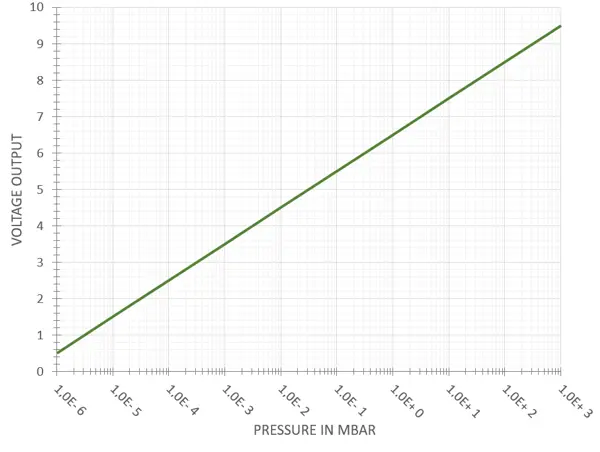

Analog Output

The analog output voltage provides a signal for external monitoring or control. The VPM-7 provides a standard voltage output of 1 VDC per decade for mbar, Torr, or Pascal.

Additionally, it can be user-configured or preconfigured with a wide range of other analog output options, allowing for seamless replacement of gauges from other manufacturers.

Digital Interfacing

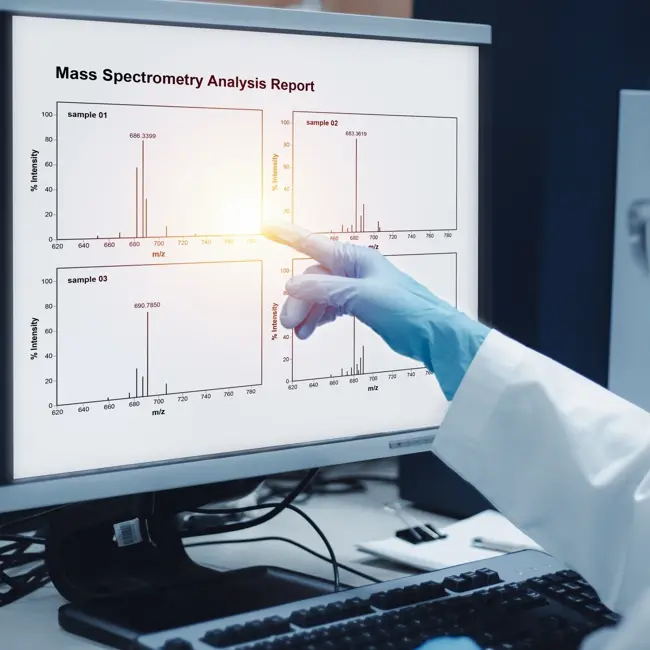

The RS-232 and RS-485 serial interfaces facilitate the transfer of pressure and temperature measurement data to external equipment.

This digital interface supports diagnostics, predictive maintenance, servicing, calibration, setpoint configuration, analog output scaling, and real-time acquisition of vacuum pressure measurements for on-screen visualization.

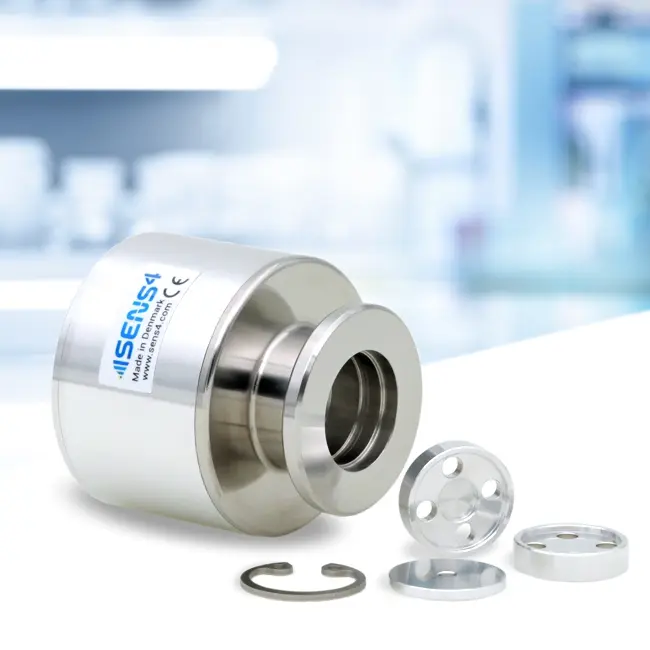

Corrosion Resistant Sensors

Typically, load-lock installations are clean and free of corrosive gases. However, the optional corrosion-resistant sensors enable the use of the VPM-7 SmartPirani™ ATM in applications where aggressive chemicals or residual etch gases are present.

Ceramic is a highly corrosion-resistant material, commonly used for vacuum sensor diaphragms in capacitance diaphragm gauges.

Parylene is a unique polymer known for its strong corrosion-resistant and hydrophobic properties.

Other Vendor Drop-in Compatibility

The VPM-7 SmartPirani™ ATM transducer is available as drop-in replacement for legacy load-lock vacuum transducers.

The pin compatibility, analog voltage pressure signal emulation, and digital protocol emulation with vacuum transducers and transmitters from other vendors.

These emulation features enable quick, seamless upgrades of traditional wire Pirani transducers, convection gauges, and legacy micro-Pirani transducers, allowing a transition to next-generation vacuum transducers without changing cabling and system equipment software.

The VPM-7 SmartPirani™ ATM will provide both cost reduction and enhanced measurement performance in many applications when replacing legacy load-lock vacuum gauges and transducers.

Customized Settings

The VPM-7 SmartPirani™ ATM transducer can be customized to meet specific application requirements, allowing it to be ready for immediate use in a particular equipment setup. Pre-configured options include measurement range, vacuum pressure unit, setpoint configuration, and output signal scaling.

Customized units are assigned a unique part number for easy reordering in the future.

Applications & Markets

The VPM-7 SmartPirani™ ATM is designed for reliable measurement and control of advanced vacuum processes and is suitable for pressure control of load-lock systems. A wide selection of VPM-7 configurations is available to meet different requirements across various industries and applications.