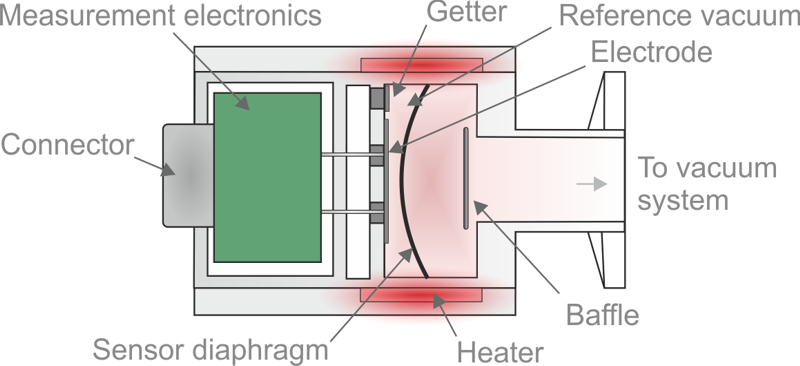

A Capacitance Diaphragm Gauge (CDG) measures vacuum gas pressure by directly measuring the applied force on the surface of a thin diaphragm. A traditional capacitance vacuum transducer measures absolute pressure, with one side of the diaphragm exposed to a permanently sealed vacuum cavity integrated into the sensor element and the other side exposed to the vacuum system and process media.

The mechanical deflection of the elastic sensor diaphragm depends on the applied pressure. The diaphragm forms an electrode, and together with an integrated auxiliary electrode, it creates a pressure-dependent capacitor that, in an electrical measurement circuit, converts the applied pressure to an electrical signal.

Pressure Measurement Range

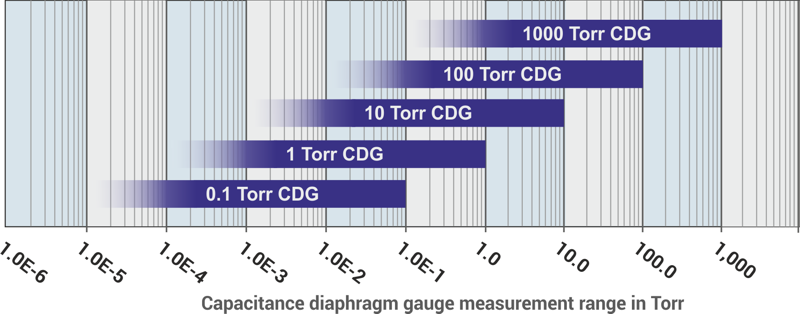

The sensitivity and low-range measurement capability of a capacitance diaphragm gauge are primarily determined by the thickness and size of the diaphragm. A large diameter and thin membrane provide the highest sensitivity and lowest vacuum pressure measurement capability.

Capacitance Diaphragm Gauge Measurement Range

A capacitance diaphragm gauge has a dynamic pressure measurement range of up to four decades. A 0.1 Torr full-scale transducer offers a useful measurement down to 1E-4 Torr (1.33E-5 mbar). Typically, three individual capacitance gauge transducers are needed to cover the measurement range from atmospheric pressure to 1E-4 mbar due to the limited dynamic range of a single sensor.

Capacitance Diaphragm Sensor Material

The preferred sensor diaphragm material for a capacitance manometer is either a ceramic like alumina (Al₂O₃) or a metal like Inconel, both of which have high corrosion resistance to aggressive gases.

Gas-Independent Measurement

Capacitance diaphragm vacuum gauges measure the direct force on the diaphragm, providing measurements independent of gas type and concentration. This gas-type-independent measurement is a key advantage, especially in applications where different gases or mixtures are used.

Measurement Accuracy

The accuracy specification of a capacitance diaphragm gauge is provided as the accuracy deviation of the reading, typically 0.1 to 0.5% of the measured value. This accuracy specification is applicable within a specific gauge range (typically 2–3 decades), varying between product types and manufacturers.

Capacitance vacuum gauges are sensitive to temperature variations, which can result in measurement offset errors. Temperature-controlled capacitance manometers have an integrated heater that stabilizes the capacitance diaphragm sensor element and improves zero-error stability in changing ambient temperatures.

The mounting orientation of the gauge can cause measurement errors due to gravitational forces on the diaphragm, especially in high-sensitivity, low-range capacitance manometers. Mounting position instructions are provided by the gauge manufacturer.

Contamination of CDG Sensor

The thin diaphragm of the capacitance gauge sensor is sensitive to contamination and corrosion. Heated capacitance diaphragm gauges help prevent material deposition on the sensor diaphragm, commonly reaching temperatures of 45 to 200 °C. Contamination or deposition on the diaphragm typically results in measurement offset errors that can be zero-adjusted by the user up to a certain point before the gauge malfunctions.

Contamination can also be minimized by protective baffles that prevent particulates from reaching the sensor diaphragm and causing deposition.

CDG Vacuum Applications

The semiconductor industry has been the primary user of capacitance diaphragm gauges, measuring and controlling vacuum gas pressure during semiconductor wafer processing. The corrosion-resistant sensor and gas-independent measurement make it ideal for semiconductor applications where aggressive gases are common.

In metrology, precision capacitance diaphragm gauges are preferred for calibrating other vacuum gauges.

In physical vapor deposition (PVD) applications, capacitance gauges are often used for pressure control in coating processes involving different gas mixtures to achieve specific coating properties.

The majority of CDG application are for civilian use, but since CDG's can be used for producing weapon technology most types of CDG's are export controlled.

Capacitance Diaphragm Gauge Paradigm Shift

Capacitance diaphragm gauges have traditionally been single-sensor standalone transducers with a limited dynamic pressure measurement range of 2–3 decades. As a result, multiple vacuum gauges were required to cover the wide dynamic pressure range (8–10 decades) needed for many vacuum applications.

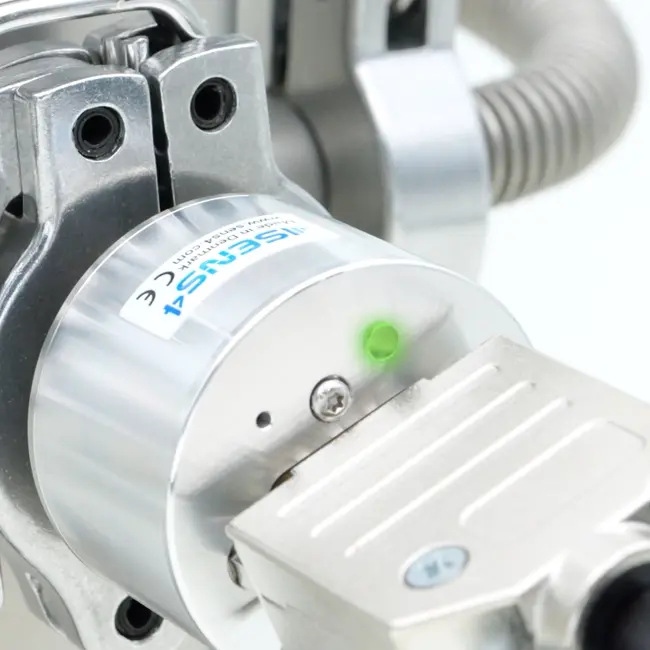

Recently, Sens4 introduced a series of wide-range combination gauges that integrate capacitance diaphragm technology with wide-range heat-loss MEMS Pirani sensor technology and piezo diaphragm sensors.

This all-in-one, capacitance diaphragm combination gauge eliminates the need for multiple vacuum sensors, simplifying vacuum system design and data acquisition while reducing the overall system cost for vacuum measurement and pressure control solutions.