From Inception to Innovation: The Evolution and Operating Principles of the Pirani Vacuum Gauge

The Pirani vacuum gauge is widely used in industrial and scientific applications to measure gas pressure indirectly by observing the heat loss from a hot metal wire suspended within the surrounding gas. This heat loss varies with gas pressure, allowing for indirect pressure measurement.

The Pirani gauge was invented and published in 1906 by Marcello Stefano Pirani¹, who developed it after encountering challenges with existing technology and then finding a novel solution. Born in Berlin on July 1, 1880, Pirani studied physics at the Technical University of Berlin-Charlottenburg, earning his Ph.D. in 1904. That same year, he joined Siemens & Halske’s lamp manufacturing division, where he worked on ramping up tantalum lamp production.

In the lamp industry at that time, McLeod² vacuum gauges were commonly used to measure vacuum levels during air evacuation and gas filling of light bulbs. However, McLeod gauges relied on a glass column containing approximately 2 kg of liquid mercury, which presented significant risks in the work environment due to exposure to mercury and mercury vapor. This spurred Pirani’s determination to develop a safer, more reliable alternative.

Pirani found inspiration in the work of Kundt and Warburg³ , who had observed and described in 1875 that: “the cooling speed of a thermometer, which can be measured with great precision, proves to be a very fine reagent for the quality of the vacuum.”

Pirani described in his first publication three modes of operation of the Pirani sensor, where either voltage, current, or filament temperature is kept constant:

- Constant voltage

- Constant current

- Constant filament temperature (resistance)

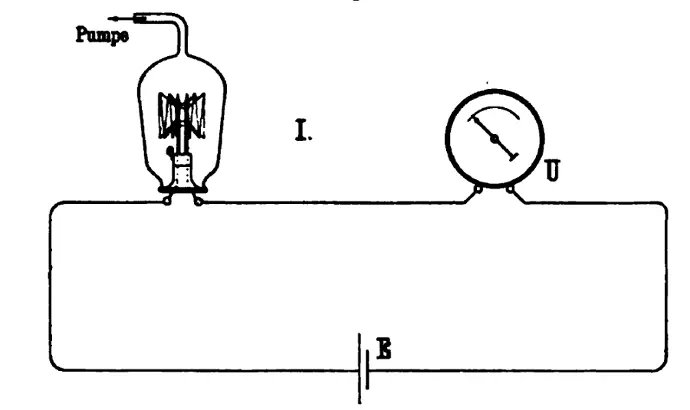

Fig. 1: Marcello Pirani used in his first experiments a tantalum lamp (L) as the heated sensor wire, connected in series with an accumulator (E) and a milliammeter (U). Illustration reprinted from ref. 1

A critical factor for all modes of Pirani sensor operation is that the sensor’s resistive wire filament must have a high temperature coefficient of resistance. This enables effective detection of temperature changes, or heat transfer from the wire, through corresponding resistance changes in relation to pressure.

Constant Voltage Pirani operation mode

Marcello Pirani described in his original publication the fixed voltage operation: “The voltage applied to the wire is kept constant, and its change in resistance or the change in the current flowing through it is observed at different pressures.”

In constant voltage mode, a fixed voltage is applied to the sensing circuit, allowing measurement of resistive changes as a function of pressure. In this mode, the power supplied to the sensor filament remains unadjusted, so the filament’s temperature varies with changes in pressure or gas density. However, due to the thermal time constants in traditional wire-based Pirani gauges, this mode of operation is generally impractical for standard metal wire Pirani sensors.

Constant Current Pirani operation mode

In constant current mode, a current source powers the sensor circuit, and resistance changes as a function of pressure are measured to determine the vacuum gas pressure. This mode of operation has trade-offs similar to those found in constant voltage mode, as described above.

Constant Temperature Pirani operation mode

Pirani also described the fixed temperature operation: “The resistance, i.e., the temperature of the wire, is kept constant, and the energy required to maintain this temperature at different levels of dilution (red. gas pressure) is observed.”

The most common operating mode for the Pirani sensor, known as constant temperature or constant resistance mode, maintains the sensor wire at a target temperature. In this mode, a control loop adjusts the power supplied to the sensor wire based on the current through a reference resistor connected in series with the sensor wire. The control loop ensures the sensor wire’s resistance matches that of the reference resistor. Since the applied power to the sensor circuit varies with pressure, it can be used to calculate the measured gas pressure.

This control loop can be managed either by an operational amplifier in a balanced Wheatstone bridge configuration or by a microcontroller unit that actively regulates power through an analog-to-digital converter. The term "constant resistance" refers to the fact that the sensor wire’s resistance—and therefore its temperature—is held at a fixed target value by adjusting the supplied power.

A fixed series resistor with the equivalent resistive value as the sensor wire at its target temperature is commonly used as a reference to maintain the sensor wire temperature in constant temperature mode.

In 1919, Masamichi So.⁴ advanced Pirani’s work, publishing his experimental study of the resistance vacuum gauge. He concluded that the thermal conductivity of air is directly proportional to pressure in the range of 1E-5 to 2E-3 Torr.

Evolution of the Pirani Vacuum Gauge

The Pirani gauge became a popular choice for a wide range of vacuum applications, and the fundamental design of using a suspended metal wire to measure heat loss, as outlined in Pirani’s first publication, is still commonly utilized in many commercial vacuum gauging products. It has gained popularity because it covers a wide dynamic measurement range using a single gauge and is a cost-effective measurement solution.

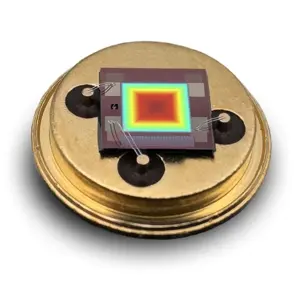

In 1993, a paradigm shift for the Pirani gauge occurred with the introduction of the first commercial MEMS (micro-electro-mechanical system) by the Danish start-up company Wenzel Electronics. The MEMS Pirani technology enabled a wider measuring range of 1-2 decades compared to competitive gauges at that time. The Wenzel MEMS Pirani gauges was operated in a Wheatstone bridge configuration as published in 1998⁵ where the sensor temperature is controlled and maintained at a target temperature of 60 oC. Wenzel Electronics later became Wenzel Instruments and was acquired by MKS Instruments Inc. in 2003.

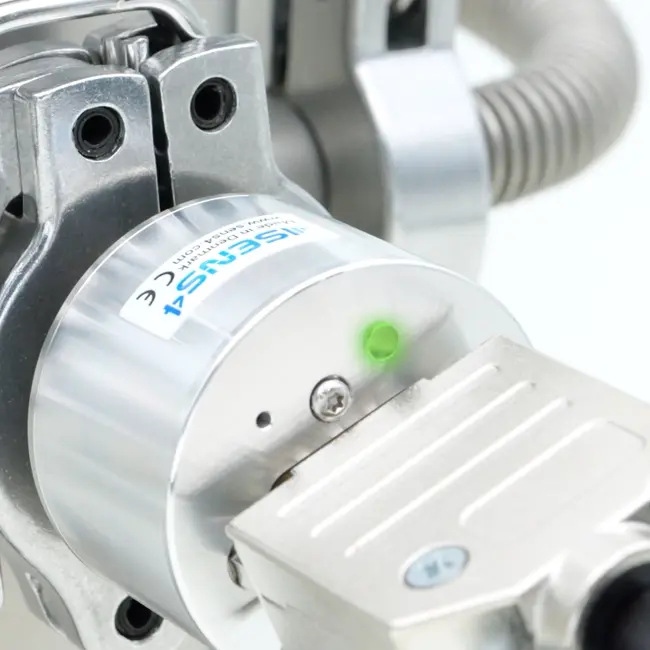

In 2019⁶ , another Danish technology company, Sens4, introduced an innovative MEMS Pirani vacuum gauging product line that pushed the boundaries of what was previously possible by extending the measuring range by an order of magnitude down to 1E-6 mbar (7.5E-7 torr).

MEMS Pirani gauges and transducers have been utilized for decades, demonstrating their benefits across diverse applications in the semiconductor industry, analytical instruments, and the coating industry. Traditionally, MEMS Pirani gauges have not been suitable for applications involving corrosive gases; however, another leap in MEMS Pirani technology was commercialized in 2023 with the introduction of ceramic-coated MEMS Pirani gauges by Sens4.

The future of Pirani Gauges

The Pirani gauge and technology continue to look promising, driven by advancements such as MEMS sensors, miniaturization, combined gauge integration, and advanced coating technologies. As an example of the latest technology achievements, a novel product named TriCAP™ was recently introduced by Sens4, which combines wide-range MEMS Pirani sensor technology with capacitance diaphragm gauge and piezo diaphragm sensor technology. The result is a wide-range, gas-independent measurement capability combined with low-pressure measurement by the MEMS Pirani.

Overall, the MEMS Pirani gauge technology is set to evolve, becoming more versatile and integrated into a wide range of applications while addressing the challenges of modern industries.

References

- Selbstzeigendes Vakuum - Messinstruments; Marcello S. Pirani, 1906, Deutsche Physikalische Gesellschaft, Verh.24(8): 686–694.

- Apparatus for measurement of low pressures of gas; McLeod, Herbert, 1874, Philosophical Magazine. xlviii (1): 110–113.

- Ueber Reibung und Wärmeleitung verdünnter Gase; A. Kundt and E. Warburg, 1875, Annalen Der Physik und Chemie.

- The Resistance Vacuum Gauge by Masamichi So., April 3, 1919.

- The MicroPirani: a solid-state vacuum gauge with wide range: O. Wenzel and C.K.Bak, Vakuum in Forschung und Praxis (1998) Nr. 4 page 298-301.

- Record-breaking ultra-wide range SmartPirani ™ vacuum transducer unveiled: Sensor land: https://www.sensorland.com/PRPages/Sens4-001.html