A Load-lock is a vacuum chamber used in the vacuum and semiconductor industry for loading devices like semiconductor wafers and transferring the wafers from ambient air pressure conditions to the main vacuum processing chamber. In the semiconductor industry, the process vacuum chamber is maintained at high vacuum pressure and not vented to ambient pressure during process cycles. An auxiliary vacuum chamber is required to isolate the wafers from the main process chamber when ventilated. These chambers are critical in semiconductor fabrication, providing a clean and stable environment for handling delicate materials.

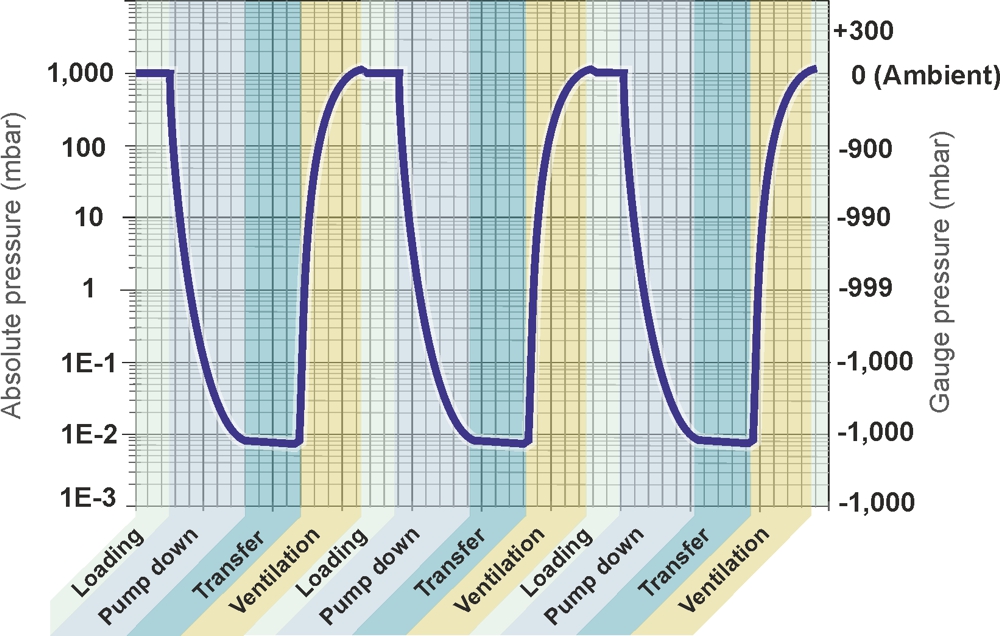

The load-lock is typically cycled between atmospheric ambient pressure and an adequate vacuum pressure required to transfer the wafers to the processing vacuum chamber via a buffer transfer chamber. Accurate control of the vacuum gas pressure in the load-lock vacuum chamber is critically important to prevent inrush of ambient air and particulate contamination of the load-lock and wafers. Contamination by inrush of ambient air will cause longer pump-down times and increases the risk of particulate contamination of both wafers and the vacuum system itself.

Load-lock pumping cycle

To control pressure during the pumping cycle, a Pirani heat-loss gauge is typically used to measure the vacuum gas pressure and to provide a set-point control signal once the vacuum pressure between the load-lock and transfer chamber is equalized. The wafer is mechanically transferred to the transfer chamber and a processed wafer is transferred back to the load-lock. The load-lock is typically ventilated with Nitrogen gas to ambient pressure or a pressure value above ambient pressure to prevent air contaminating the load-lock chamber.

Load-lock venting to atmosphere cycle

To control the pressure in the venting cycle a vacuum sensor measuring relative to ambient pressure, commonly known as a gauge sensor, is used. The advantage of using a gauge sensor instead of an absolute sensor is that the load-lock pressure can be accurately equalized to zero differential pressure between the load-lock vacuum chamber and ambient pressure independently of variation in ambient pressure due to weather changes.

Load-lock operation and pressure cycles

Load-lock applications

Fast cycle time of the load-lock is important to optimize the wafer processing cost. Load-locks play a vital role in enhancing the precision, efficiency, and reliability of semiconductor fabrication processes, ultimately leading to the production of high-quality semiconductor devices. Use of accurate and modern load-lock pressure control can shorten cycle times.

Load-lock vacuum systems are not only used in the semiconductor industry, but also in analytical equipment, like scanning electron microscopes, where samples are transferred from ambient pressure to the analysis vacuum chamber.

In a PVD (Physical Vapor Deposition) system, it can also be an advantage to maintain the processing deposition chamber under permanent vacuum pressure and only having to vent an axillary load-lock vacuum chamber.

Single-chamber PVD systems have a large door system to the ambient pressure to load the carousels with the coating objects. The large door surface requires accurate control of the venting process to both prevent over pressurization of the vacuum chamber and to equalize the pressure to open the door.

Many vacuum processes and types of vacuum systems, where samples, wafers, test objects, substrates or other devices need to be transferred from ambient air to the vacuum system, can benefit from having an auxiliary load-lock system to ensure fast cycle-times, system uptime, reduced particulate contamination and water vapor contamination.

It also offers a record-breaking wide range that, in some applications, can eliminate the need for hot or cold cathode combination gauges for load-lock applications, where low transfer pressure level is required.

The SmartPirani™ ATM transducer can replace an atmospheric switch, a diaphragm vacuum transducer and a heat-loss Pirani transducer used on older load-lock systems – or it can be a performance upgrade on load-lock vacuum systems using legacy load-lock transducers.