Drop-in replacement Vacuum Gauge Explained

A drop-in replacement refers to a product, component, or system designed to be a direct substitute for another, requiring no or minimal modifications to the existing setup. It is engineered to match the physical dimensions, interfaces, and functional specifications of the original item, allowing for seamless integration into the system it replaces.

Drop-in replacements are commonly used in many industries such as electronics and computing.

In the vacuum industry, drop-in replacements are widely adopted by many vendors offering vacuum gauges that meet the form, fit, and function of a competitive product.

For equipment manufacturers and factories relying on vacuum measurement solutions, a lack of drop-in alternatives can lead to high dependence on single-source suppliers. Qualifying a drop-in replacement gauge is a crucial safeguard to ensure business continuity in the event of unexpected supply chain disruptions. For example, in 2023, a major vendor of vacuum gauges experienced a cyberattack that caused significant supply-demand imbalances for months. Applied Materials ¹ reported an estimated US$250 million negative impact in the second fiscal quarter of 2023 as a result of that supplier's cyberattack. This incident underscored the importance of ensuring business continuity by having a qualified second-source supplier, particularly in industries like semiconductor manufacturing.

When qualifying a second-source vacuum gauge, the following parameters should be assessed and evaluated:

- Match of Analog Pressure Signal Scaling: Ensure the replacement gauge provides equivalent output scaling.

- Connector Pin Compatibility: Verify that the connectors and pin configuration align with the original device.

- Relay Setpoint Functionality: Confirm the relay configuration matches operational requirements.

- Digital Communication Protocol Emulation: Ensure the replacement supports compatible communication protocols.

- Geometry Compatibility: Check that physical dimensions align with system requirements (if applicable).

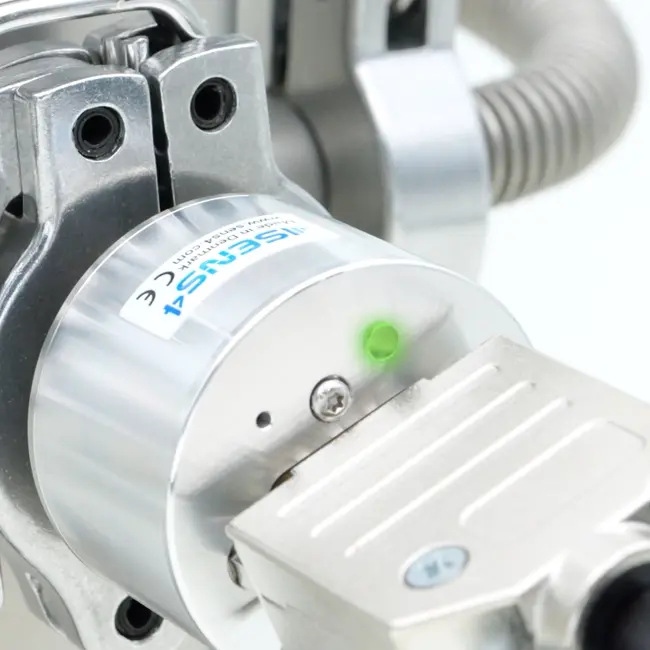

Sens4 offers drop-in replacement vacuum measurement solutions that often provide performance enhancements and cost savings compared to original products.

References

1. US$250 million ‘negative impact’ at Applied linked to cyberattack EENEWS Europe February 21, 2023