A vacuum switch is an electronic or mechanical device that provides an electrical switching contact function at a defined vacuum gas pressure level. It is used in many vacuum applications for pressure control purposes and safety interlock functionality.

A multistage turbomolecular pumping system requires an adequate vacuum pressure level to operate, and a vacuum switch can be used to control the pump and protect it from operating at excessively high pressure.

The fore-line vacuum pump controls the fore-line vacuum pressure required for the turbomolecular pump to function. When the fore-line vacuum pressure reaches the predefined switching point, the vacuum switch closes a relay contact that provides an electrical signal to start the turbomolecular pump.

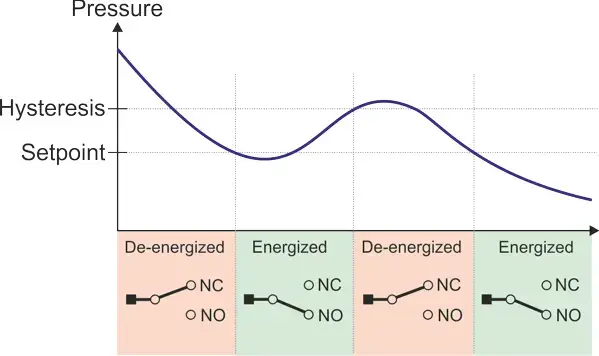

To prevent a vacuum switch from becoming unstable and producing irregular oscillations due to measurement noise or pressure pulsing, two different switch points are normally defined. These are commonly referred to as the setpoint value and the hysteresis value. A typical situation is illustrated in the figure to the right. When the vacuum pressure crosses the setpoint value, the vacuum switch relay is energized, and the normally open contact closes. It will open again when the hysteresis value is exceeded. The choice of using the normally closed or the normally open contacts depends on the desired state of the contact when the relay is de-energized.

Relay Switches

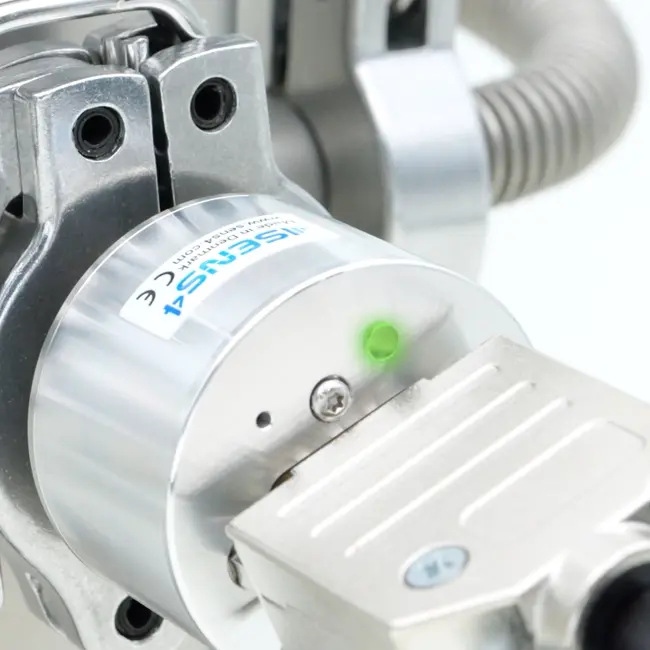

In modern vacuum equipment design, vacuum switches are often an integrated part of the vacuum measurement equipment. A vacuum transducer can have multiple independent mechanical- or solid-state relay switches that are controlled by one or more vacuum pressure sensors. The SmartPirani™ transducer is an example of a wide range vacuum transducer with three independent high-performance solid-state relays with closing and breaking contacts.

Load-lock Pressure Switch

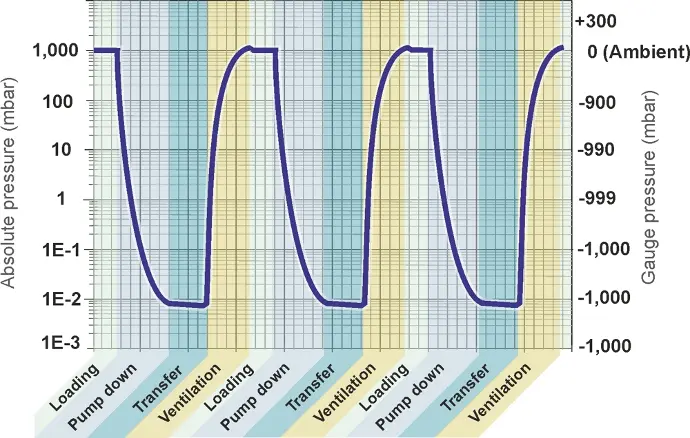

In semiconductor manufacturing equipment, wafers are transferred from ambient air pressure to the vacuum processing chamber using a load lock. The vacuum gas pressure in a load-lock chamber requires to be accurately controlled to prevent ambient air and particulate contamination. A combination of pressure- and vacuum switches are typically used to control the pumping and ventilation cycles.

Accurate and repeatable vacuum pressure control and surveillance is critical in many vacuum processes and applications. The industry has moved from mechanical vacuum switches to electronic vacuum switches.