Diamonds CVD

Vacuum technology plays a crucial role in the growth of synthetic diamonds used in jewelry and for industrial purposes.

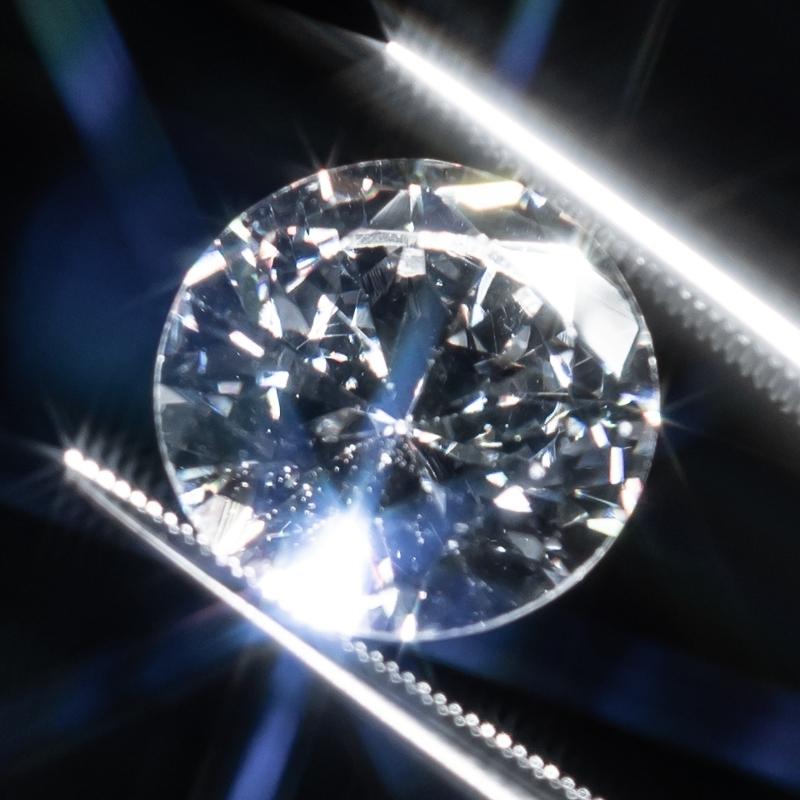

In nature, diamonds are formed deep within the Earth’s mantle over millions of years, through a process called crystallization. They are formed from carbon atoms that bond in a unique crystal lattice structure as a result of exposure to extreme pressure and high temperatures.

There is an alternative to mining diamonds by use of Chemical Vapor Deposition (CVD) to grow synthetic diamonds. The typical process is Microwave Plasma Chemical Vapor Deposition (MPCVD), which is a specific variation of the CVD. The process takes place under vacuum pressure and involves generation of plasma that reacts with a hydrocarbon gas such as methane. This plasma contains highly reactive carbon species, which are deposited onto a substrate, typically a diamond seed or a piece of silicon, to form a diamond layer. The process of creating a synthetic diamond by use of CVD typically takes several weeks.

Recommended Vacuum Gauges for MPCVD

Microwave Plasma Chemical Vapor Deposition (MPCVD) equipment utilized typically rotary vane or scroll vacuum pumps and consequently the base pressure is relatively high. The process pressure is generated by flow of the process gas and maintained in the range of 100-200 mbar. During processing reactive radicals from the plasma is generated and the VDM-2 corrosions resistant diaphragm gauge offers a robust solution in such environments.

We also provide drop-in compatible products that seamlessly integrate with gauges from other vendors, allowing for a smooth transition from existing measurement solutions without the need to change cables or system software.

Get in touch with the Sens4 team for more information

We highly appreciate questions, feedback, and customer dialogue.