Alternative to Capacitance Diaphragm Gauges

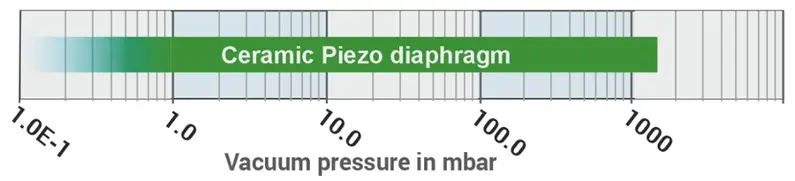

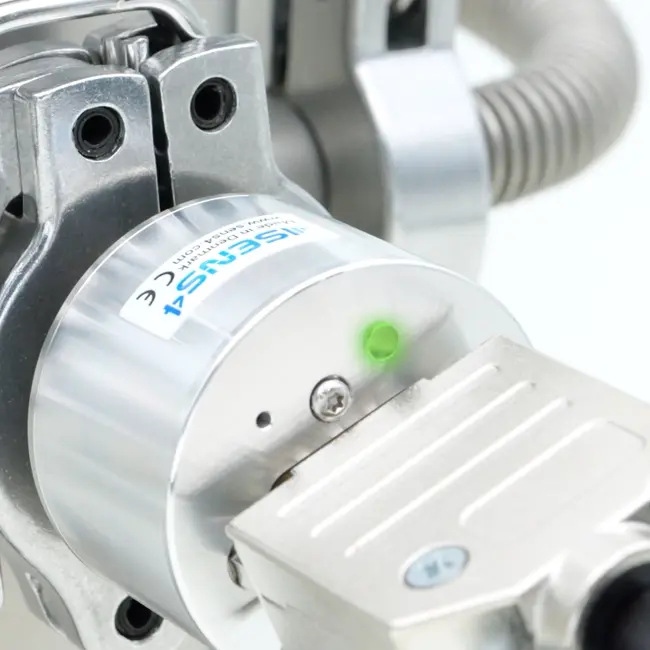

Capacitance diaphragm gauges are used in many vacuum applications for measurement and control of advanced processes. The VDM-2 transducer is a cost-effective and compact alternative to traditional 1000 Torr/mbar full-scale Capacitance Diaphragm Gauges (CDGs).

Engineered for Harsh Vacuum Environments

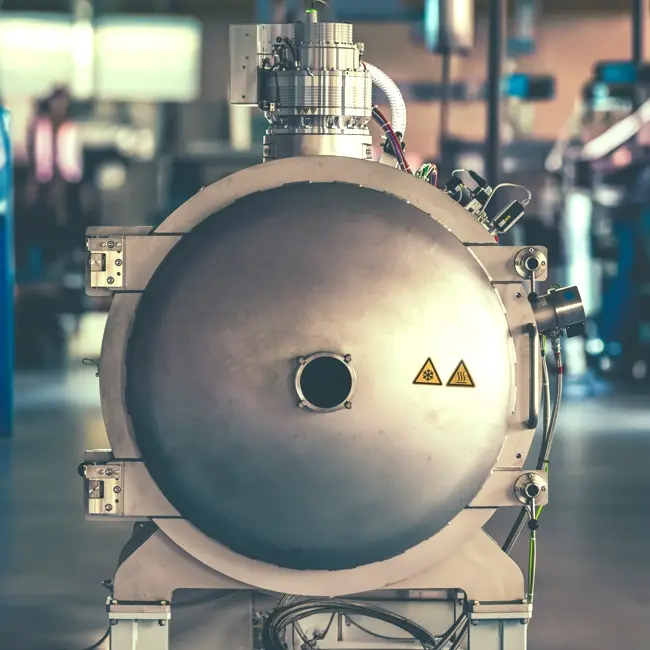

The VDM-2 vacuum transducer is specifically designed for use in demanding vacuum applications where corrosive gases, aggressive chemicals, or harsh process conditions are present. Its ceramic aluminum oxide diaphragm provides exceptional corrosion resistance to a wide range of solvents, acids, and reactive compounds, ensuring long-term reliability in challenging environments.

For even greater protection, the VDM-2 is available with an optional Parylene coating—a highly corrosion-resistant and hydrophobic polymer barrier. Parylene is widely used in medical applications, including hydrogen peroxide plasma sterilization and lyophilization, where durability and contamination resistance are critical.

In vacuum processes prone to particle contamination, an optional protective baffle prevents deposition of particulates on the sensor diaphragm, safeguarding measurement accuracy and sensor longevity.

Built for resilience, the aluminum oxide sensor element is engineered to withstand sudden venting and overpressure conditions up to 2 bar absolute (29 psia), making it ideal for high-stress vacuum systems in industrial, pharmaceutical, and semiconductor environments.

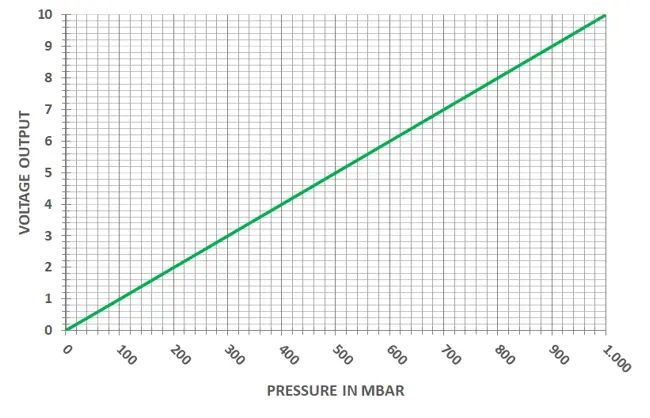

Flexible Analog Voltage Output for Pressure Readout and Control

The VDM-2 vacuum transducer features a high-resolution analog voltage output, enabling direct connection to external displays, data acquisition systems, PLCs, or process control equipment for real-time vacuum pressure monitoring.

Compatible with a wide range of systems, the VDM-2 offers multiple preconfigured analog output curves, allowing for seamless drop-in replacement of vacuum gauges from various manufacturers—minimizing setup time and integration effort.

For custom applications, the analog output can also be user-configured with arbitrary linear scaling, providing maximum flexibility to match specific system requirements or control strategies.

Digital Interface with RS-232 and RS-485 for Reliable Vacuum Data Transmission

The VDM-2 vacuum transducer features integrated RS-232 and RS-485 digital interfaces, ensuring reliable, noise-free transmission of vacuum measurement data over long cable distances—without signal degradation or interference from electrical noise.

This digital communication interface supports advanced functions such as real-time pressure monitoring, diagnostics, predictive maintenance, calibration, service status, setpoint configuration, and analog output scaling. These capabilities enable enhanced system control and simplify integration into modern vacuum systems.

Even when the analog output is configured for a limited range (e.g., 100 Torr full scale), the digital output continues to deliver accurate, full-range vacuum pressure readings up to 1333 mbar (1000 Torr), providing maximum flexibility for monitoring and control.

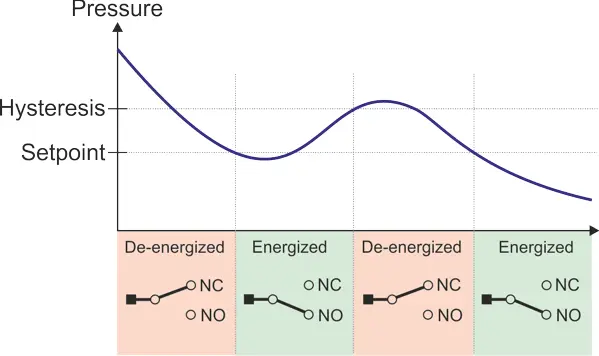

Reliable Solid-State Relays for Advanced Vacuum System Control

The VDM-2 vacuum transducer is equipped with three independent solid-state switch relays for direct control of external devices such as vacuum pumps, valves, and safety interlock circuits. These integrated outputs enable seamless automation and real-time system response in demanding vacuum control applications.

Compared to traditional electromechanical relays, solid-state relays deliver faster switching speeds, greater reliability, and arc-free operation, while eliminating electromagnetic interference (EMI) during switching—ideal for precision and noise-sensitive environments.

Built for durability, the VDM-2’s relays are UL-listed, CSA-recognized, and certified to EN/IEC 60950-1 standards, ensuring long-term performance and safety in critical vacuum processes and high-cycle industrial applications.

Compatible with Other Vendor Gauges – Drop-In Replacement Vacuum Transducers

Sens4's drop-in replacement vacuum transducers are engineered for full compatibility with other vendor gauges, featuring connector pin-out compatibility that allows for seamless installation without the need for rewiring.

These high-performance transducers emulate the analog output scaling and measurement range of equivalent vacuum gauge models from leading manufacturers, ensuring accurate and consistent performance across systems.

In addition, Sens4 vacuum transducers support digital protocol emulation, enabling plug-and-play integration with existing vacuum controllers, power supplies, and display units—without requiring changes to the communication software. This makes them the ideal choice for vacuum system upgrades, replacements, and OEM integrations where interoperability is essential.

Customized Vacuum Transducer Settings – Tailored for Your Application

The VDM-2 vacuum transducer can be factory-configured to meet your specific application requirements, ensuring optimal performance and seamless integration right out of the box. Custom configuration options include:

- Measurement range

- Vacuum pressure units (e.g., mbar, Torr, Pa)

- Setpoint configuration

- Output signal scaling

These pre-configured transducers are ideal for OEMs and system integrators looking for plug-and-play installation with minimal setup time.

Each customized VDM-2 unit is assigned a unique part number, simplifying future reordering and ensuring consistency across your vacuum systems.

Applications & Markets

The VDM-2 Ceramic Diaphragm Vacuum Transducer is engineered for high-accuracy vacuum measurement and control in demanding industrial and scientific environments. Designed for long-term stability and reliability, it supports a wide range of vacuum applications across multiple sectors.

Typical applications include:

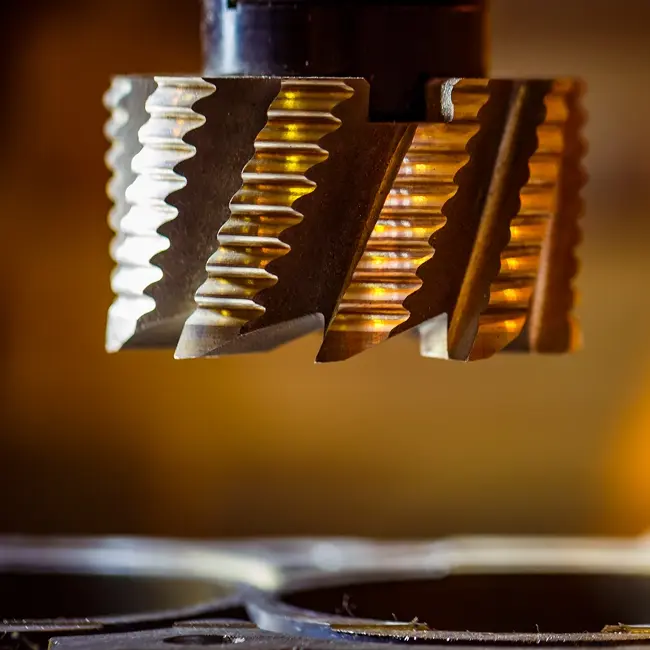

- Semiconductor manufacturing

- Laboratory research and instrumentation

- Industrial vacuum systems

- Analytical and process equipment

- Leak detection and quality control

To meet diverse performance and integration needs, a broad range of VDM-2 vacuum transducer configurations is also available, making it easy to find the right solution for your specific process requirements

Distillation

Measure vacuum gas pressure when simulating the harsh environment of space.

Vacuum Fore-line

Measurement and surveillance of vacuum fore-line for protection of turbo molecular vacuum pumps.