Spinning Rotor Gauges, commonly referred to as SRG or viscosity gauges, measure the pressure-dependent molecular drag on a magnetically levitated spinning steel ball. During the SRG vacuum measurement cycle, the spinning steel ball is accelerated to a well-defined rotational speed, and the deceleration time is measured to determine the molecular drag on the ball. This molecular drag is mathematically converted into a vacuum gas pressure value. In the high-pressure regime, the higher gas density results in greater molecular drag, while in the low-pressure regime, the molecular drag is reduced. A longer measurement cycle is required when measuring low pressure due to the extended deceleration time. The typical spinning rotor gauge measurement cycle is 3–30 seconds.

The SRG vacuum gauge measurement depends on the gas type and gas concentration.

The spinning rotor gauge can be used for vacuum measurement in the range of 5E-7 to 1 mbar (1E-5 to 100 Pa).

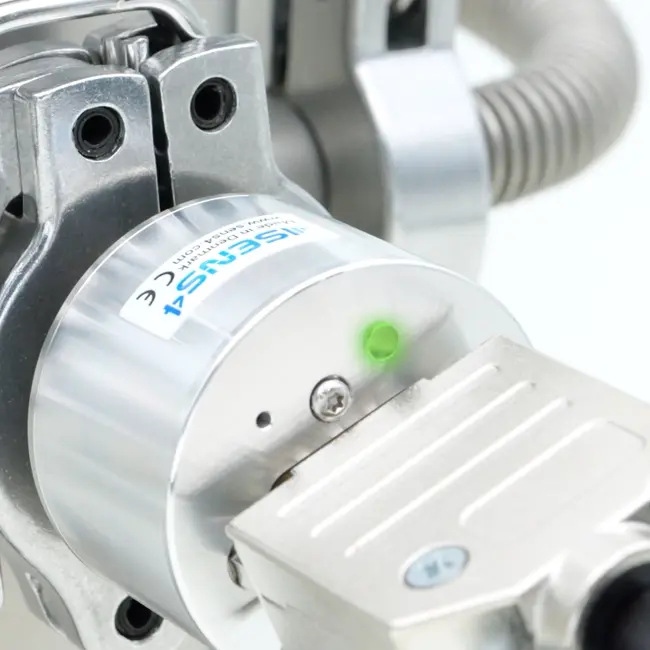

The spinning rotor gauge sensor device consists of a steel ball inside a tube. The sensing head includes the surrounding electronics and coils to drive and measure the steel ball rotation. During the measurement loop the magnetic driving coil accelerates the spinning steel ball to hundreds rps (rotations per second) after which the driving coil is de-energized. The measurement coil then measures the rotations of the ball during the deceleration time period. The deceleration rate of the ball is a function of the pressure-dependent molecular drag.

- Sensing ball levitation coil

- Sensing ball element

- Sensor tube

- Rotation driving coil

- Permanent magnet

- Measurement coil

- Damping coil

- Vacuum flange

Applications:

- Cryogenic and Liquid Gas Vessels:

SRG sensors ensure optimal vacuum levels (<1×10⁻² mbar) in cryogenic tanks used for storing liquids like oxygen, nitrogen, and argon. By embedding the sensor, vacuum integrity can be verified without breaking the vacuum. - Vacuum Insulation Panels (VIP):

Embedded SRG sensor elements enable in-situ quality checks of vacuum pressure inside insulation panels, ensuring effective insulation. Applications extend to vacuum-insulated glass (VIG), where continuous vacuum verification enhances performance. - Rate-of-Rise Outgassing Testing:

With stainless steel as the only exposed material, the SRG is ideal for outgassing and leak testing using the rate-of-rise principle. - Vacuum Calibration:

Trusted for decades in metrology and calibration labs, SRG instruments serve as precision transfer standards for vacuum calibration.

The SRG sensor’s unique design and functionality make it indispensable across diverse industries requiring reliable vacuum measurement and control.