Diaphragm Sensor Technology

The PCM-1 transducer is based on a ceramic aluminum oxide sensor diaphragm that converts applied pressure into an electrical signal. The sensor element features a dry-cell diaphragm design without any oil filling.

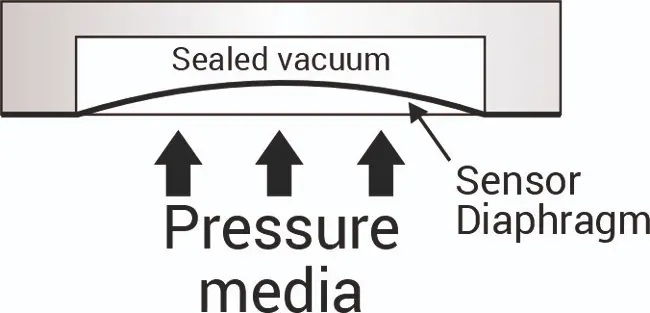

Absolute Sensor

Absolute pressure measurement refers to the pressure exerted by a gas, vapor, or liquid relative to a perfect vacuum. A perfect vacuum, defined as zero pressure, serves as the fixed reference point for determining absolute pressure measurement values.

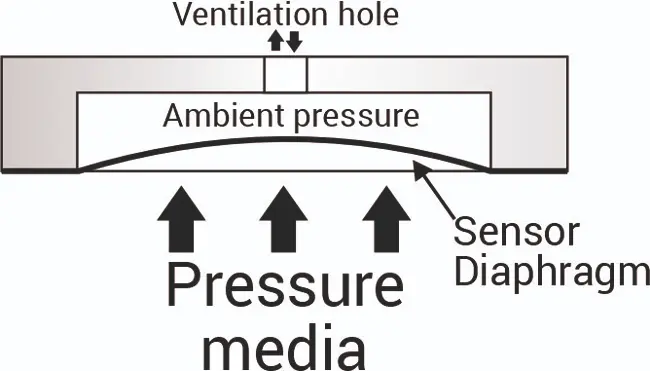

Gauge Sensor

Gauge pressure is the pressure measured relative to the surrounding atmospheric pressure. One side of the diaphragm is exposed to the pressure medium being measured, and the other side is exposed to ambient atmospheric pressure.

At atmospheric pressure, the gauge measurement will read zero. It will show a negative value if vacuum pressure is applied and a positive value if the device is exposed to positive pressure.

Built for tough Environments

The ceramic sensor surface, combined with the 316 stainless steel flange and internal Viton® sealing, offers excellent chemical resistance and compatibility with a wide range of aggressive gases, solvents, and acids.

Titanium flange is available for corrosive applications where stainless steel is not applicable.

The PCM-1 sensor is built to last and can withstand continuous vibrations and rapid pressure changes from vacuum to atmosphere. Each product is individually tested, calibrated, and compensated for drift related to temperature changes. Calibration data is stored in internal non-volatile memory.

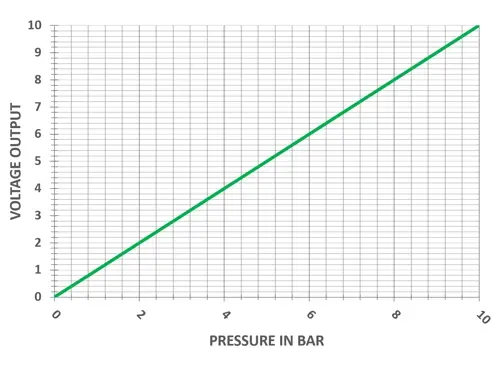

Analog Voltage Output

The analog output provides a voltage or current signal for external pressure readout or controls.

The PCM-1 is available in versions with traditional analog output (e.g., 4-20 mA and 0-10 VDC) and various optional digital interfaces.

S4-Connect™ Programmer

The innovative S4-Connect™ USB digital communication interface provides access to the powerful digital core. It enables digital communication over the power supply line, eliminating the need for additional connector pins. This interface can be used for diagnostics, maintenance, service, calibration, setpoint configuration, analog output scaling, and customization of other parameters. Additionally, the products offer pin compatibility with industry-standard pin-outs for analog transducers.

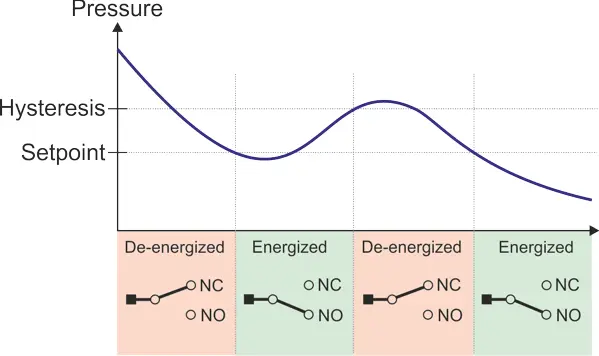

Process Pressure Control and Surveillance

The optional setpoint can be used for controlling or monitoring measured pressure via a solid-state relay. Basic control employs on/off regulation with a programmable setpoint and hysteresis value.

Advanced Enclosure Design

The IP67-sealed 316 stainless steel enclosure with an integrated hydrophobic membrane is designed for extreme environments. The innovative moisture control barrier prevents internal moisture accumulation and water condensation when ambient pressure, temperature, and humidity fluctuate. Gauge pressure sensors measure relative to ambient pressure, and the hydrophobic membrane provides pressure equalization during changes in ambient conditions, such as weather or altitude variations.

Customized Settings

The PCM-1 transducer can be delivered with a custom configuration to match specific application requirements and work for a specific equipment installation out of the box. Examples of pre-configured options include measurement range, vacuum pressure unit, setpoint configuration, and output signal scaling.

Customized products will be assigned a unique part number for easy and straightforward future reordering.

Applications & Markets

The PCM-1 is designed for harsh industrial environments. A wide selection of PCM-1 configurations is available to meet different requirements across various applications.

Semiconductor

The PCM-1 enable pressure measurement and control of gas supply in semiconductor applications.

Automation

Measure and control pressure in industrial pneumatic applications.